Hey there! If you’re involved in the space industry, you know that testing electronics for space missions is a big deal. TAU Systems is shaking things up with their compact accelerators, bringing a fresh approach to how we test space electronics. These nifty devices offer radiation-testing-as-a-service, which is a game-changer for making sure our space tech can handle the harsh cosmic environment.

Hey there! If you’re involved in the space industry, you know that testing electronics for space missions is a big deal. TAU Systems is shaking things up with their compact accelerators, bringing a fresh approach to how we test space electronics. These nifty devices offer radiation-testing-as-a-service, which is a game-changer for making sure our space tech can handle the harsh cosmic environment.

As we reach further into the cosmos, ensuring that electronics on satellites and spacecraft are tough enough to withstand cosmic radiation becomes more important than ever. Traditional methods are often pricey and not very accessible, but TAU Systems is here to offer a more efficient and cost-effective solution.

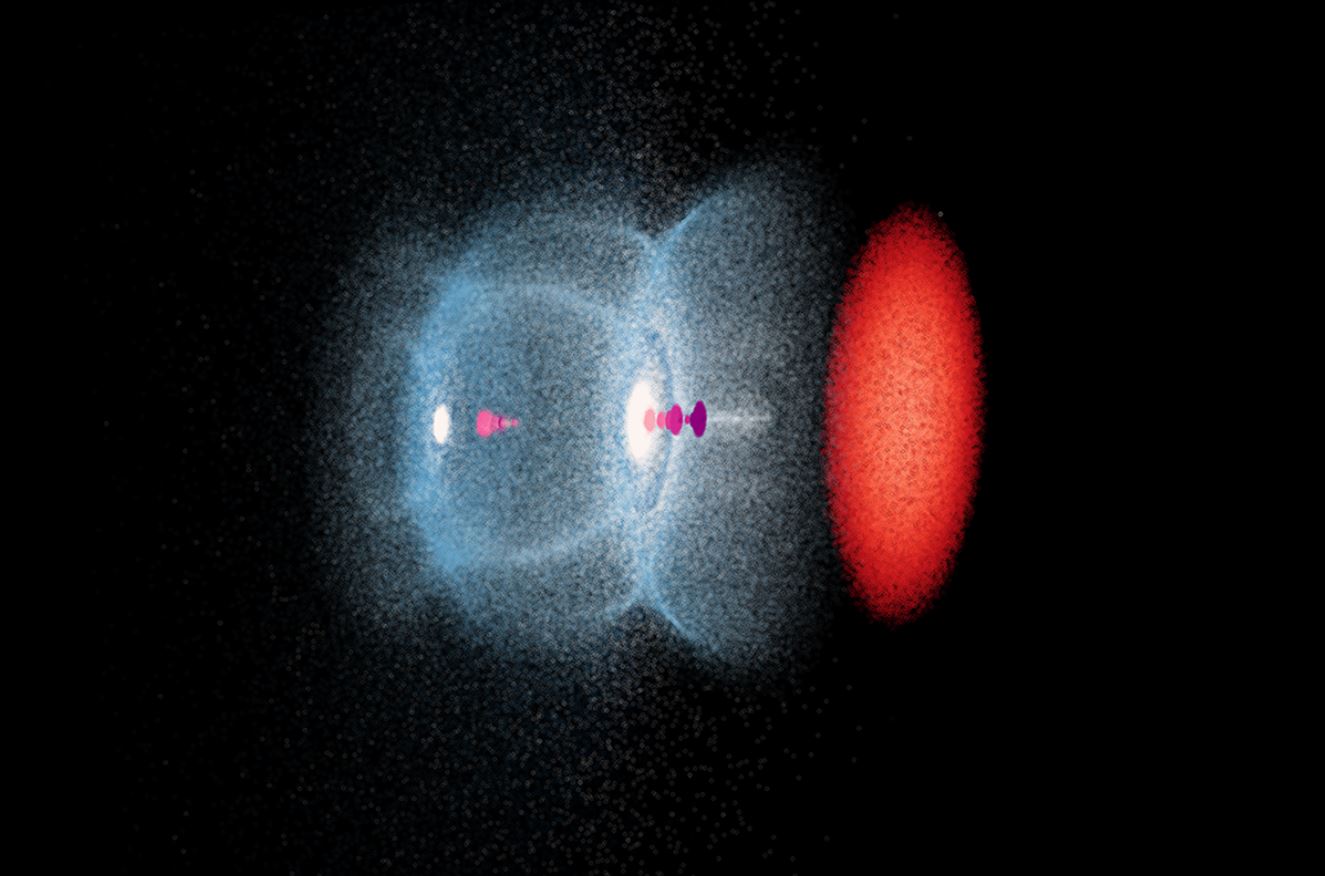

Space electronics face a tough challenge called Single Event Effects (SEE). These occur when high-energy particles mess with electronic components, potentially causing temporary or even permanent damage. The complexity and power of today’s transistors make them more vulnerable. While radiation-hardened electronics are a thing, they haven’t fully embraced AI and machine learning yet because the chips need to be developed and tested to handle cosmic radiation.

In the past, SEE testing relied on large, expensive ion accelerators that weren’t easy to access, creating a bottleneck in the process. TAU Systems is changing the game with their compact, affordable Laser Wakefield Accelerator (LWFA) technology. These systems are small enough to fit in a shipping container but powerful enough to produce high-energy electron beams for precise testing.

By making SEE testing more available, TAU Systems is helping ensure that crucial space technologies, like next-gen satellites and exploration probes, are built to last. Their U.S.-based facility, TAU Labs, is set to offer up to 4,000 hours of beam time per unit each year, significantly boosting access to these essential services.

But it’s not just about accessibility. TAU’s compact accelerators offer precision testing by simulating the high-energy cosmic radiation found in space, making sure the tests reflect real-world conditions. Plus, their compact design slashes operational costs compared to traditional testing methods. The scalability of these systems means they can meet the growing demands of the industry, with multiple facilities generating thousands of hours of beam time annually.

TAU’s technology isn’t just limited to SEE testing. It’s got a range of other applications, including medical imaging, semiconductor development, and cancer treatment research. This innovation bolsters the global space industry, which is rapidly expanding due to commercial ventures, government programs, and defense initiatives. Ensuring the durability of electronics in defense satellites and strategic assets is more crucial than ever.

The scalability of TAU’s technology allows for quick iteration and deployment of new satellite designs, letting private space companies innovate without being held back by outdated testing infrastructures. This progress not only strengthens the technological backbone of the space industry but also speeds up the deployment of next-generation space capabilities.

As the space industry adopts more complex and intelligent technologies, the demand for reliable, cost-effective SEE testing solutions like those from TAU Systems will only grow. By making high-energy SEE testing more accessible, TAU is helping to reduce risks in space missions, enhance satellite longevity, and support the next wave of space innovation. This advancement is crucial for the future of exploration, ensuring that our technological ambitions can withstand cosmic challenges.

For satellite manufacturers, space agencies, and defense contractors looking to gain a competitive edge in space electronics, investing in advanced SEE testing solutions like those offered by TAU Systems is a smart move. As we venture further into the cosmos, the reliability of our electronics will be key to the success of our missions. With ultrafast compact accelerators leading the next generation of SEE testing, space-bound technologies will be more robust, reliable, and ready for the extreme realities of space.