Imagine hopping on a ferry that doesn’t just get you from point A to point B but does so with a smaller carbon footprint. That’s exactly what researchers at the University of Sharjah are aiming for with their innovative approach to ferry travel. They’re swapping out those traditional diesel engines for something a bit more futuristic: pneumatic propellers.

Imagine hopping on a ferry that doesn’t just get you from point A to point B but does so with a smaller carbon footprint. That’s exactly what researchers at the University of Sharjah are aiming for with their innovative approach to ferry travel. They’re swapping out those traditional diesel engines for something a bit more futuristic: pneumatic propellers.

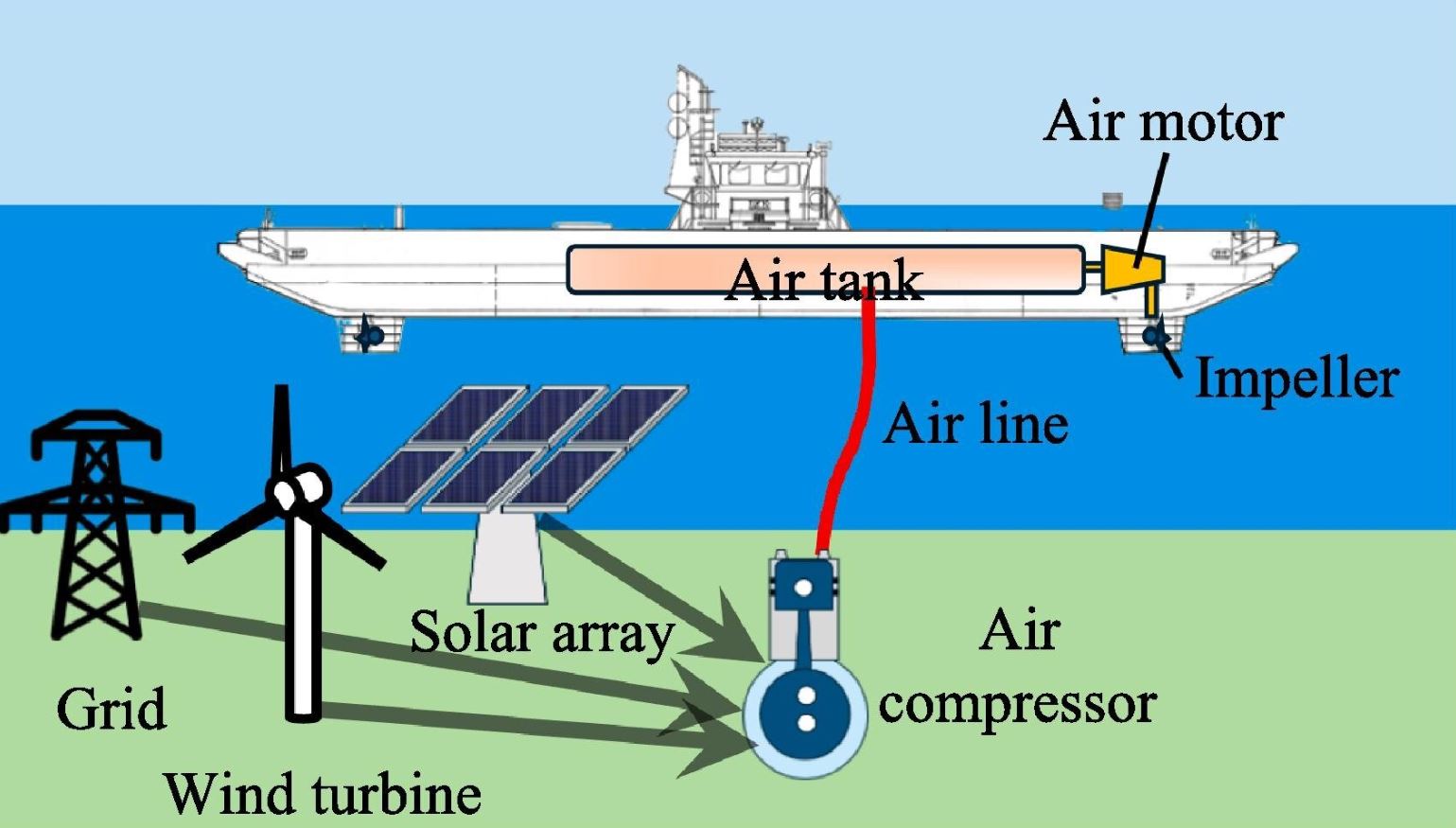

So, what’s the big deal about these pneumatic propellers? Well, they’re powered by compressed air and come with some pretty impressive benefits. They’re cleaner, quieter, and kinder to our environment. Each air motor packs a punch with 250 kW of power, just right for ferry routes in places like Finland. This research, published in Energy Conversion and Management, dives deep into how feasible this alternative really is for short-distance maritime transport.

Diesel engines are powerful, no doubt, but they guzzle fuel and contribute significantly to pollution. That’s where pneumatic propellers shine. As Abdul Hai Alami, the lead author, points out, these engines can be seamlessly integrated into the ferry’s structure or even in auxiliary tanks, boosting buoyancy and efficiency.

The team’s research smartly uses polytropic relations to model airflow from pressurization to motor propulsion, showing that this method can handle various maritime conditions. The system pairs high-pressure air tanks with vane air motors and naval impellers, promising reduced operational costs and a solid payback period.

They even tested this system on a Finnish ferry built in 1985, and it performed admirably. Kaj Jansson, a co-author from K. J Marineconsulting Ab, highlighted how predictable pneumatic propulsion can be on fixed routes, which means less worry about fluctuating oil prices.

Economically speaking, the numbers are compelling. You’re looking at potential savings of USD 73,000 and an eight-year payback period. Plus, the system can scale up or down to meet different operational needs, all while matching the performance of diesel engines.

Professor Alami is optimistic about the industry embracing this new propulsion method. With ongoing advancements in vane air motors, even more powerful pneumatic engines are on the horizon. The research suggests that the payback period could be even shorter under the right conditions.