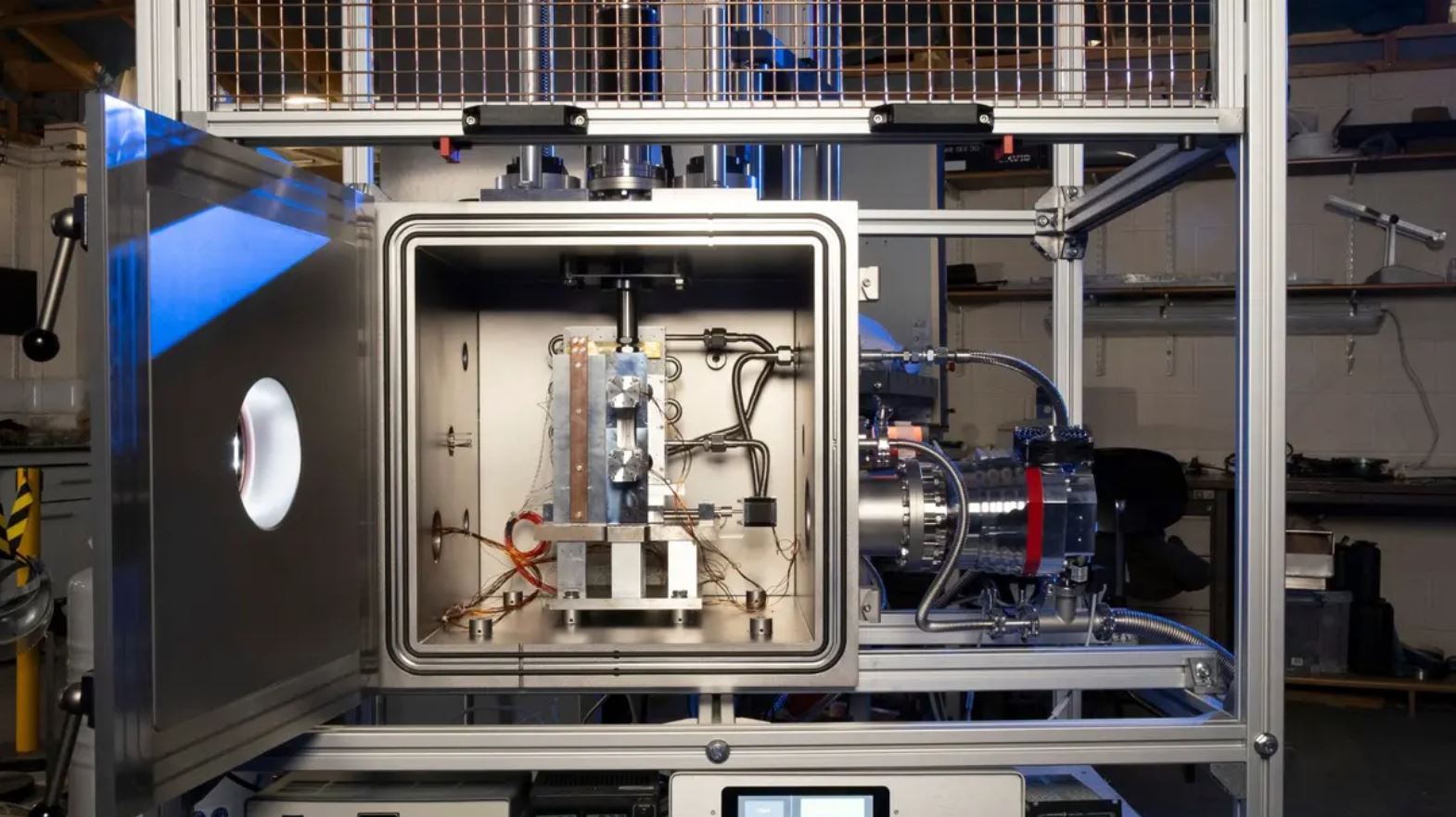

Glasgow’s new NextSpace Testrig is giving 3D-printed space materials a proper test drive. Developed by the University of Glasgow’s James Watt School of Engineering, this facility is the world’s first built specifically to check that 3D-printed polymers, ceramics, and metals can handle the extreme conditions of space. If you’ve ever wondered whether on-demand space parts could stand up to harsh environments, this is a significant step forward.

Glasgow’s new NextSpace Testrig is giving 3D-printed space materials a proper test drive. Developed by the University of Glasgow’s James Watt School of Engineering, this facility is the world’s first built specifically to check that 3D-printed polymers, ceramics, and metals can handle the extreme conditions of space. If you’ve ever wondered whether on-demand space parts could stand up to harsh environments, this is a significant step forward.

Dr. Gilles Bailet, one of the driving forces behind the project, explains, “The NextSpace Testrig is open to academic colleagues, researchers and commercial clients from around the world to help them ensure that any materials they plan to 3D print in space will work safely.” By replicating everything from bone-chilling lows of -150°C (-238°F) to scorching highs of +250°C (500°F) and applying forces equivalent to a 2,000-kilogram weight, the facility offers a real-world glimpse into the challenges of space construction.

As astronauts have relied on 3D printing to produce tools and parts on the spot ever since NASA introduced a printer aboard the International Space Station in 2014, ensuring the structural integrity of these prints is more important than ever. Without reliable materials, broken pieces could become hazardous debris hurtling through space like a speeding bullet.

With its automated magazine system for testing multiple samples in one go, the NextSpace Testrig not only speeds up the process but also sets the stage for safer, more efficient on-orbit assembly. Backed by the UK Space Agency’s Enabling Technology Programme, this innovation is poised to help the UK space sector stay competitive on a global scale and might one day support the construction of complex structures, like solar reflectors on the Moon.