SCHURTER, the Swiss tech leader, has introduced a new high‑current UHP fuse designed specifically for humanoid robots. This innovative surface‑mount device protects essential battery systems and power electronics in increasingly compact robotic designs.

SCHURTER, the Swiss tech leader, has introduced a new high‑current UHP fuse designed specifically for humanoid robots. This innovative surface‑mount device protects essential battery systems and power electronics in increasingly compact robotic designs.

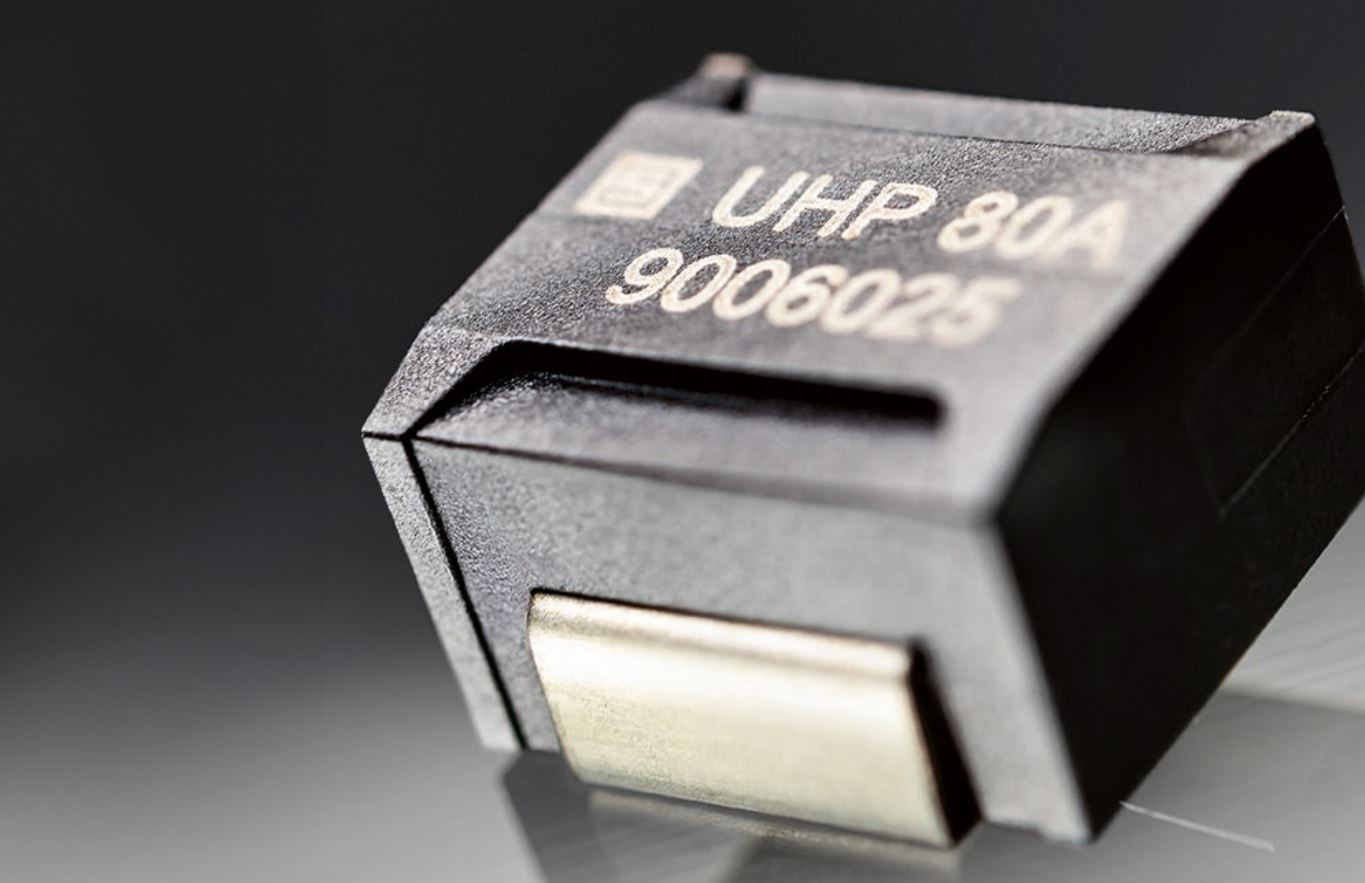

Engineered for primary circuits in space‑constrained, high‑density environments, the fuse’s ultra‑compact design means it integrates seamlessly into the intricate architectures of modern robots. It delivers reliable protection without demanding extra room—a real bonus for developers tackling miniaturisation challenges.

For those designing the next generation of robotics, this component offers dependable safeguarding for parts like high‑efficiency battery packs and motor controllers. By using off‑the‑shelf elements like SCHURTER’s UHP fuse, manufacturers can streamline production while keeping pace with growing market demands.

Conveniently provided in tape‑and‑reel packaging, the fuse adheres to UL and RoHS compliance standards. It supports a rated current of up to 100 A with a breaking capacity of 2000 A at 80 VDC or 3000 A at 63 VDC, safely tripping in 15 seconds at twice its rated current. Its robust performance over a temperature range from –55°C to +125°C makes it ideal for modern automated assembly lines.

As humanoid robotics rapidly evolves— with industry pioneers like Hyundai Motor Group and GXO deploying systems from Boston Dynamics and Agility Robotics—components that address both efficiency and reliability are essential. If you’ve ever struggled with integrating protection in tight spaces, you’ll appreciate how SCHURTER’s UHP fuse simplifies and optimises the design process.