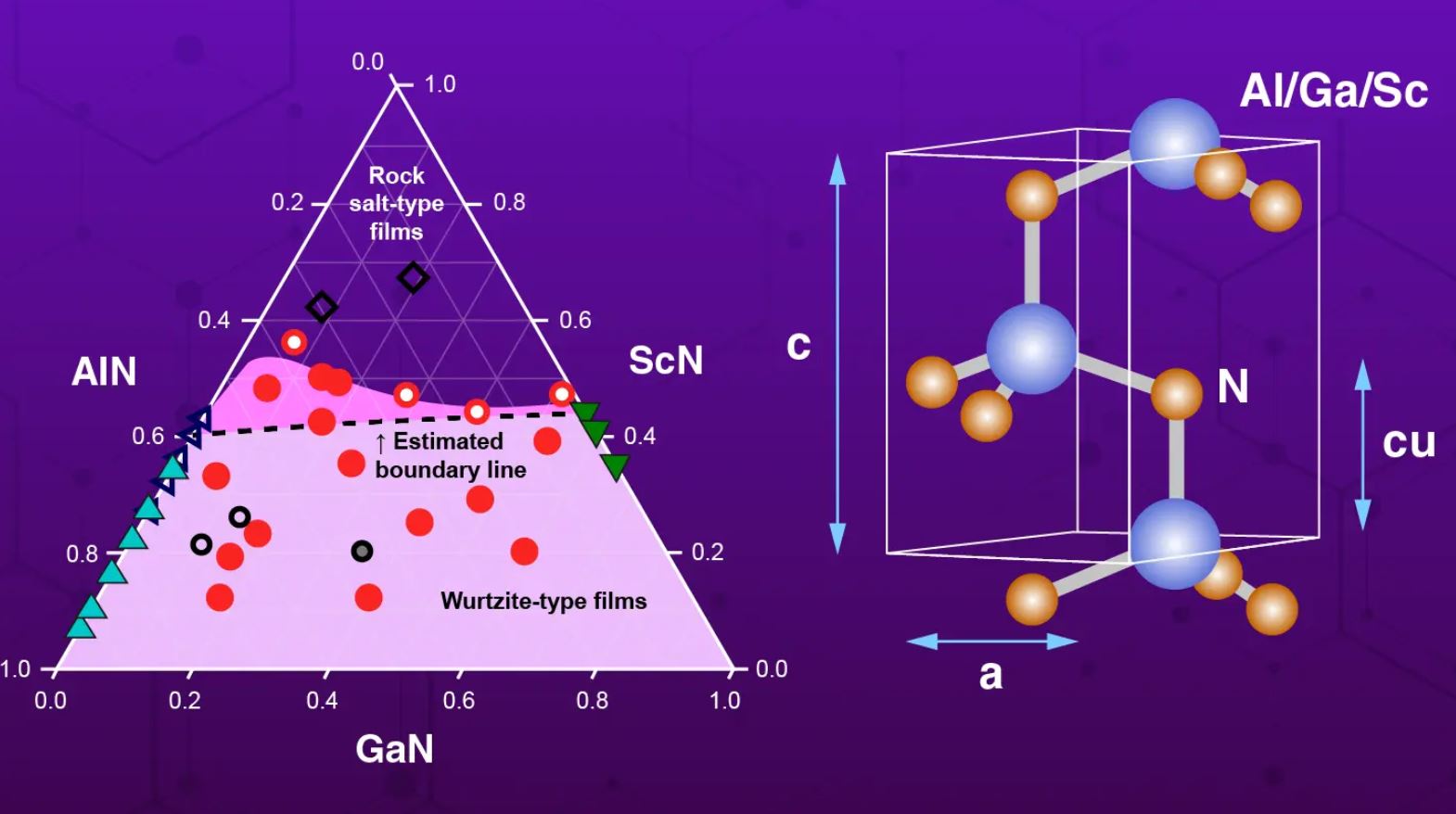

Researchers at the Institute of Science Tokyo have pushed the envelope on ultra‐low-power memory devices by engineering ternary alloy films with a higher scandium content. These new (Al,Ga,Sc)N films—crafted using reactive magnetron sputtering—solve previous stability issues and could soon reshape how we think about memory in our increasingly compact yet powerful electronics.

Researchers at the Institute of Science Tokyo have pushed the envelope on ultra‐low-power memory devices by engineering ternary alloy films with a higher scandium content. These new (Al,Ga,Sc)N films—crafted using reactive magnetron sputtering—solve previous stability issues and could soon reshape how we think about memory in our increasingly compact yet powerful electronics.

If you’ve ever struggled with devices that guzzle power even when idle, then the potential of these films might catch your eye. The non‑volatile ferroelectric memories in discussion maintain data without a constant electrical supply. Thanks to the unique crystal structures of gallium nitride (GaN) and aluminum nitride (AlN), these films can support switchable polarization, a feature crucial for modern data storage. However, incorporating enough scandium into these materials was a challenge—until now.

Under the guidance of Professor Hiroshi Funakubo, the research team notably boosted the scandium levels in (Al,Ga,Sc)N films by fine-tuning the mix of AlN and GaN, which helped scandium integrate more effectively into the crystal lattice. Using reactive magnetron sputtering, the team deposited thin films on silicon substrates. They then employed advanced techniques such as X‑ray diffraction and electron microscopy to check the films’ crystal structure and overall properties.

One standout achievement was lowering the coercive field—the electric field needed to flip polarization—from 5.8 MV/cm to 1.8 MV/cm by increasing the scandium content. As Professor Funakubo explained, this significant reduction is an encouraging sign for the next generation of memory devices. Beyond data storage, these films also boast enhanced piezoelectric and optoelectronic characteristics, making them promising candidates for applications like noise filters in emerging 6G communications and low‑power optical computing systems.

This work marks a decisive step towards more energy‑efficient memory technologies that could ultimately lead to more sustainable, high‑performance electronics. For anyone keen on seeing how small tweaks in material composition can lead to big improvements, these findings offer plenty to think about.