Alt. Leather, an innovative Australian startup, is shaking up the leather industry with a fresh alternative made entirely from plant-based materials and recycled textiles. This new material is designed to mimic traditional leather, providing a sustainable option for fashion, footwear, upholstery, and automotive industries.

Alt. Leather, an innovative Australian startup, is shaking up the leather industry with a fresh alternative made entirely from plant-based materials and recycled textiles. This new material is designed to mimic traditional leather, providing a sustainable option for fashion, footwear, upholstery, and automotive industries.

According to Alt. Leather’s website, 10% of their ingredients are upcycled from textiles and cellulose that would otherwise end up in landfills or be incinerated. The rest comes from regenerative plants that are abundant worldwide. The company is also exploring how their material can be both degradable and recyclable, ensuring it stays eco-friendly throughout its lifecycle.

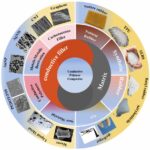

Traditional leather production, which has been around for about 7,000 years, often involves chemicals to treat animal hides. On the flip side, synthetic leathers usually come from petroleum-based plastics like polyurethane (PU) and polyvinyl chloride (PVC). Alt. Leather’s founder, Tina Funder, saw a clear need for a more sustainable leather alternative. By choosing eco-friendly ingredients such as cellulose, starches, recycled fibers, and plant resins, the company has significantly reduced the environmental impact typically associated with leather production.

Alt. Leather emphasizes their environmental impact by noting that their production process emits roughly three times less greenhouse gases than conventional leather. It also uses 30 to 70 percent less energy than PU/PVC synthetic leathers. Plus, they cut energy consumption by 60 to 65 percent and water usage by half compared to traditional methods.

The startup’s journey has been supported by the Commonwealth Scientific and Industrial Research Organisation (CSIRO). With cutting-edge green technology, Alt. Leather has managed to replicate the complex 3D network structure of natural leather using plant fibers. Their new material meets international standards for durability and aesthetics.

Initially, Alt. Leather tested their material with small extruder machines. The results were promising, leading to trials with larger equipment to explore mass production. Through CSIRO’s Kick-Start program, they accessed advanced facilities and expert advice, which helped refine their processes. Funder noted, “The structured approach of Kick-Start allowed us to test our material in a real-world setting and confirm that it could be scaled up.”

Participation in CSIRO’s India-Australia RISE Accelerator program gave Alt. Leather access to manufacturing capabilities in India, where their material was successfully used to produce handbags and footwear in Noida and Chennai. Funder reflected, “The real-world production runs in India provided valuable insights into the operational challenges of mass manufacturing. It allowed us to fine-tune our approach at an industrial scale and further improve the efficiency of our processes.”

With ongoing support from CSIRO, Alt. Leather aims to enhance its sustainable material through further formulation testing, with the hope of significantly reducing the environmental impact of traditional leather production.