Imagine turning something as simple as a loaf of bread into a vital component for the future of clean water technology. Sounds a bit out there, right? Well, that’s exactly what engineers at **Saint Vincent College**, working alongside the University of Pittsburgh, have managed to achieve. They’ve come up with two inventive methods to transform bread into carbon electrodes, and it’s all about being kinder to our planet. If you’re curious, their groundbreaking work is detailed in the Royal Society Open Science journal.

Now, you might be wondering why bread. Well, it turns out bread is one of the most wasted food items worldwide, and using it in this way could cut down on ecological waste. The journey began with Adam Wood, who first dabbled with stale bread for producing electrodes. This new research builds on his foundation, pushing the envelope further.

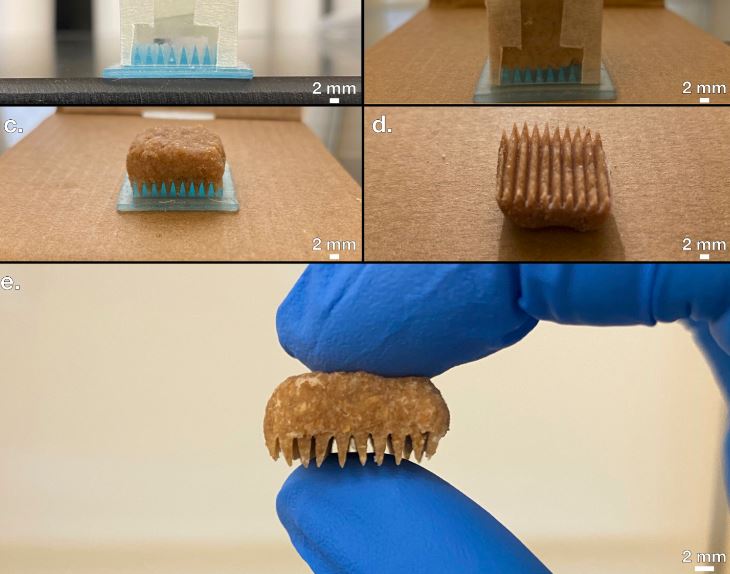

In their recent experiments, the team used Pepperidge Farm whole-wheat bread. They heated it to a scorching 800°C in an environment devoid of oxygen, morphing the bread into carbon electrodes. The real magic here is in their ability to shape these electrodes precisely.

Let me walk you through their two techniques. First, there’s the 3D-printed mold method, which allows for precise shaping. Picture a zigzag mold—that’s what they experimented with, and it worked like a charm! On the flip side, the second method involves mixing bread with water, blending it up, and shaping it before the heating process. This technique results in sturdier electrodes.

So, which method is better? Well, it all depends on what you’re after. The 3D-printed mold gives you those exact shapes, while the blending method gives you a more durable product. Both are steps toward affordable, environmentally-friendly electrodes that could revolutionize desalination systems, bringing fresh water to those in need globally.

Looking ahead, the team is focused on refining these processes and gearing up for mass production of these ‘green’ electrodes. It’s all part of a bigger plan to roll out a cost-effective capacitive desalination solution. Exciting times, right?