Researchers at MIT have developed a new resin that reacts distinctly to different kinds of light. When exposed to ultraviolet (UV) light, the resin hardens into a strong, durable material; under visible light, it transforms into a form that dissolves easily in certain solvents. This means you can now print complex objects with recyclable support structures.

Researchers at MIT have developed a new resin that reacts distinctly to different kinds of light. When exposed to ultraviolet (UV) light, the resin hardens into a strong, durable material; under visible light, it transforms into a form that dissolves easily in certain solvents. This means you can now print complex objects with recyclable support structures.

If you’ve ever struggled with wasted support material in 3D printing, this innovation could change your approach. Traditional vat photopolymerization builds items layer by layer and uses extra material for supports—only to see it discarded later. With the new method, you simply submerge your completed print in a solution, and the supports dissolve away, leaving behind the robust UV-cured structure.

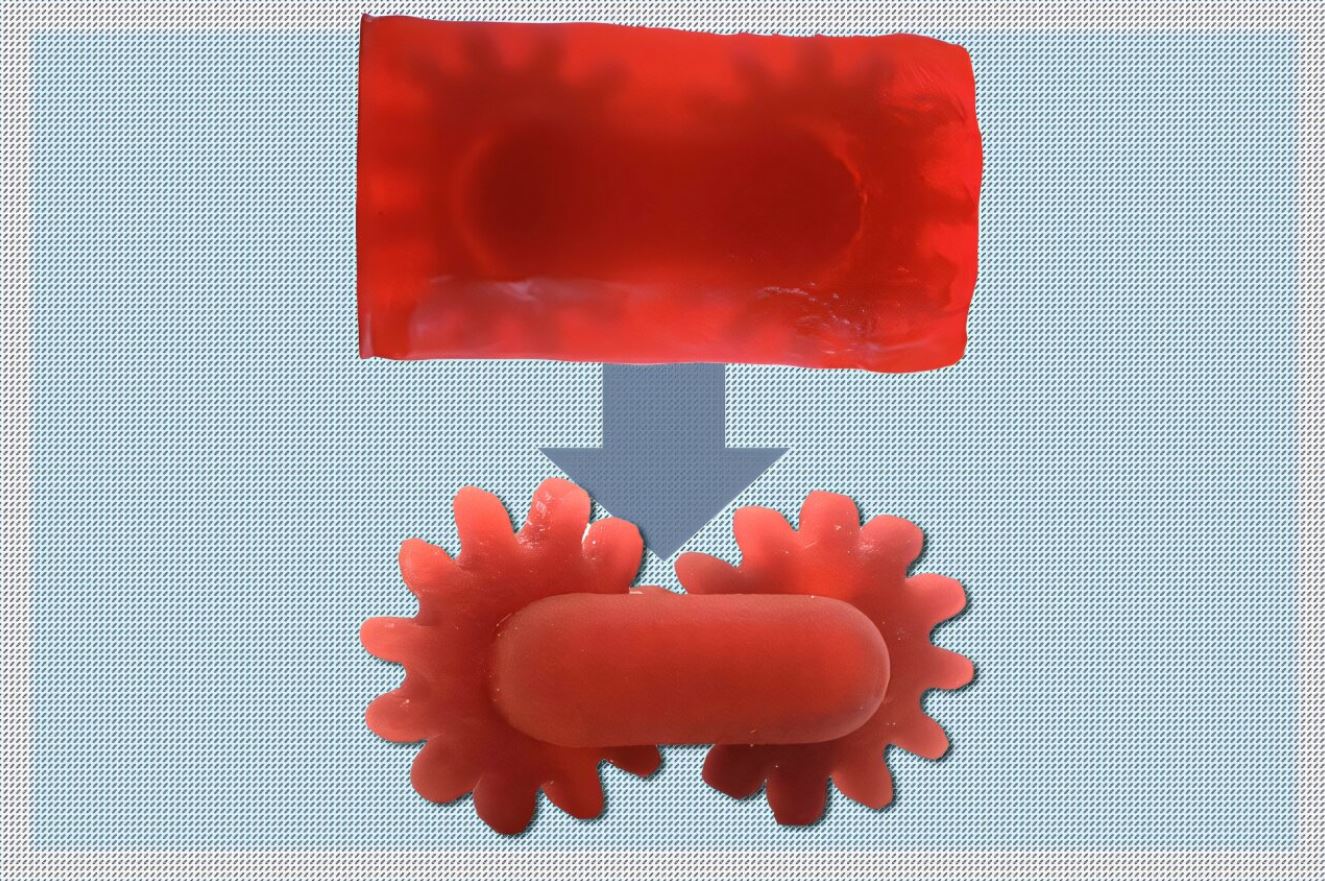

MIT engineer Nicholas Diaco explains, “With this advancement, you can now produce multipart assemblies with interlocking components in a single print and simply wash away the supports.” This technique not only improves efficiency but also lets you recycle the support material onsite, significantly reducing waste.

The secret lies in the resin’s formulation. By mixing two commercially available monomers, the team achieved a dual response: under UV light, the molecules lock together tightly, whereas with visible light, they remain separate and are easily washed away. A third, “bridging” monomer was later added to counter issues with weaker UV curing, ensuring that the supportive structure remains stable during printing.

The researchers showcased the method by crafting intricate designs—ranging from functional gear trains to complex lattice structures. One striking example featured a small dinosaur encased in an egg-shaped support, which could be dissolved post-printing. This approach paves the way for sustainable, resource-efficient manufacturing, whether you’re creating custom hearing aids, dental implants, or other specialised products.