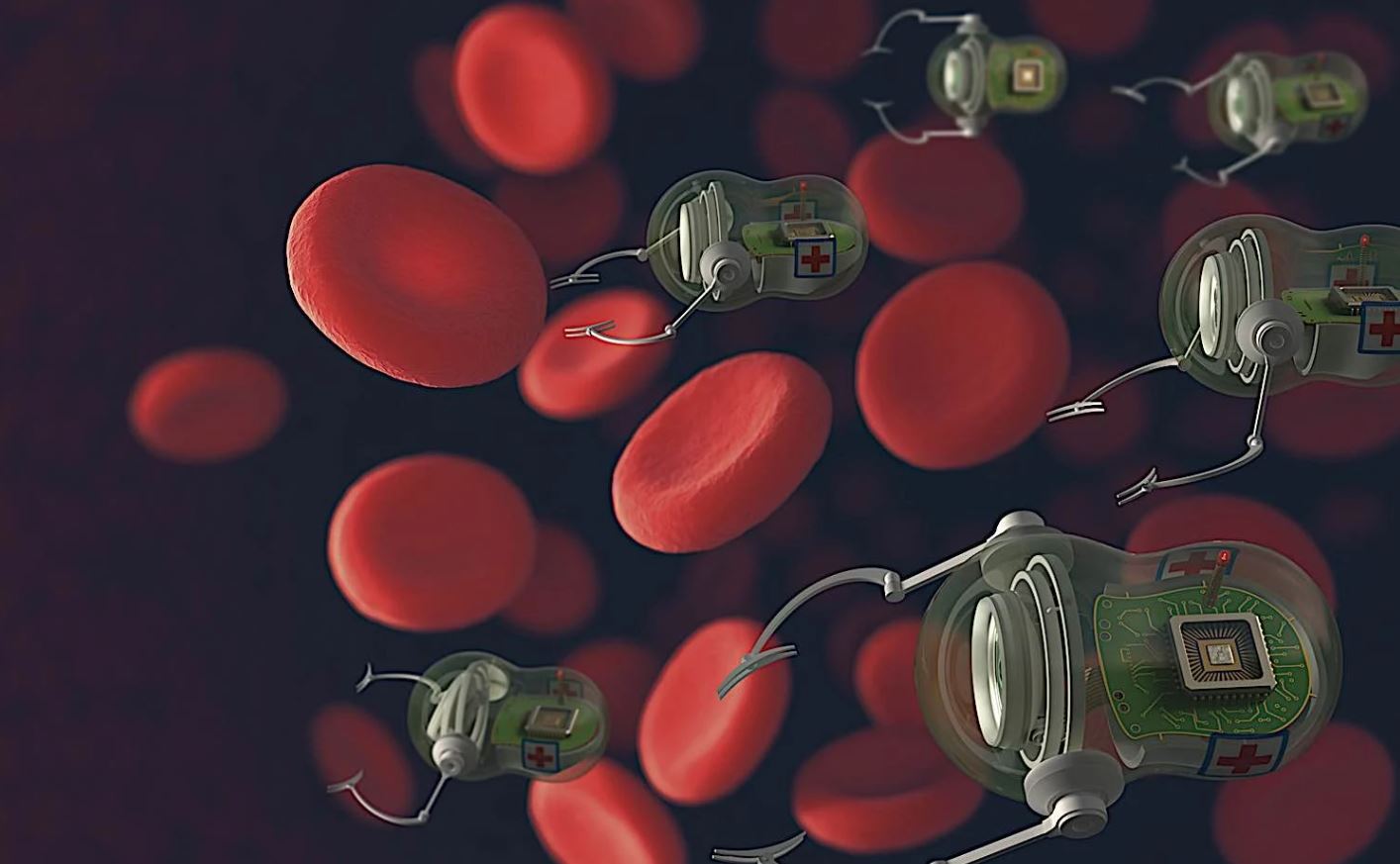

Imagine robots that are as flexible as the cells in your body. Sounds like science fiction, right? Well, thanks to a team of brilliant researchers in Korea, this is now a reality. They’ve developed tiny liquid robots that draw inspiration from the natural flexibility of biological cells. These little machines, about the size of a grain of rice, are crafted from water encased in Teflon particles. This design allows them to mimic the adaptable nature of human cells.

Imagine robots that are as flexible as the cells in your body. Sounds like science fiction, right? Well, thanks to a team of brilliant researchers in Korea, this is now a reality. They’ve developed tiny liquid robots that draw inspiration from the natural flexibility of biological cells. These little machines, about the size of a grain of rice, are crafted from water encased in Teflon particles. This design allows them to mimic the adaptable nature of human cells.

Controlled using sound waves, these robots are quite the multitaskers. They can maneuver through barriers, collect debris, and glide effortlessly over various surfaces. What’s really fascinating is their ability to act as miniature chemical reactors. In experiments, two robots, each carrying a different chemical compound, merged without damage. This allowed their contents to mix and react within their protective Teflon shells.

The potential applications for these liquid robots are vast and exciting. Their biocompatibility opens doors to medical uses, such as delivering treatments to otherwise hard-to-reach parts of the body, like chemotherapy drugs targeting tumors. Plus, their ability to incorporate additional molecular tools presents opportunities for advanced disease diagnostics.

As the team put it, “It is challenging to emulate biological forms and functions with artificial machines.” But they believe that harnessing the supreme deformability of liquids while providing stable yet flexible shells around them is a promising avenue to tackle this challenge.

These robots share a conceptual lineage with the fictional T-1000 from “Terminator 2: Judgment Day,” known for its liquid metal form. While previous attempts to create similar machines used liquid metals responsive to electromagnetic fields, these materials were unsuitable for chemical or biological applications. An alternative approach involves using liquid marbles—water droplets encased in a hydrophobic barrier. This method leverages capillary interaction, stabilizing the droplets into near-solid beads.

Traditional liquid marbles have limitations, such as vulnerability to temperature changes or pressure, but the new robots overcome these challenges with a reinforced Teflon shell. By optimizing the Teflon-to-water ratio, the researchers enhanced the durability of the robots. Freezing water into cubes before coating with Teflon powder created an even stronger structure, as melting reduces volume and compresses the Teflon particles, forming a robust armor.

Testing these enhanced robots against traditional liquid marbles revealed their superior resilience. The Teflon-coated bots maintained their integrity under stress and were less prone to bursting. Employing sound waves, researchers maneuvered these robots through complex tasks, including navigating obstacle courses and merging to form larger entities. Their hydrophobic nature enables them to traverse both water and solid surfaces seamlessly, unlike older liquid marbles, which often failed.

To evaluate their capabilities, the team orchestrated a mission where two robots collaborated to neutralize a chemical toxin. One robot retrieved the toxin, while the other collected an antidote, culminating in a merger that neutralized the substance. Although these robots remain manually controlled and small, future developments aim to incorporate smart materials for autonomous operations.

This technology, currently utilizing water and Teflon, could eventually adapt to include other materials, paving the way for diverse and versatile liquid robots.