Researchers at Tokyo Metropolitan University have developed a smart, cost‑effective method to strengthen magnesium alloys, a vital material in electric vehicle manufacturing. If you’ve ever struggled with the anxiety of material corrosion, this new approach—using the natural action of bubbles forming and collapsing—offers a fresh solution. By carefully channeling the power of cavitation, the team crafted a liquid‑based chemical conversion coating that not only saves money but also bolsters durability.

Researchers at Tokyo Metropolitan University have developed a smart, cost‑effective method to strengthen magnesium alloys, a vital material in electric vehicle manufacturing. If you’ve ever struggled with the anxiety of material corrosion, this new approach—using the natural action of bubbles forming and collapsing—offers a fresh solution. By carefully channeling the power of cavitation, the team crafted a liquid‑based chemical conversion coating that not only saves money but also bolsters durability.

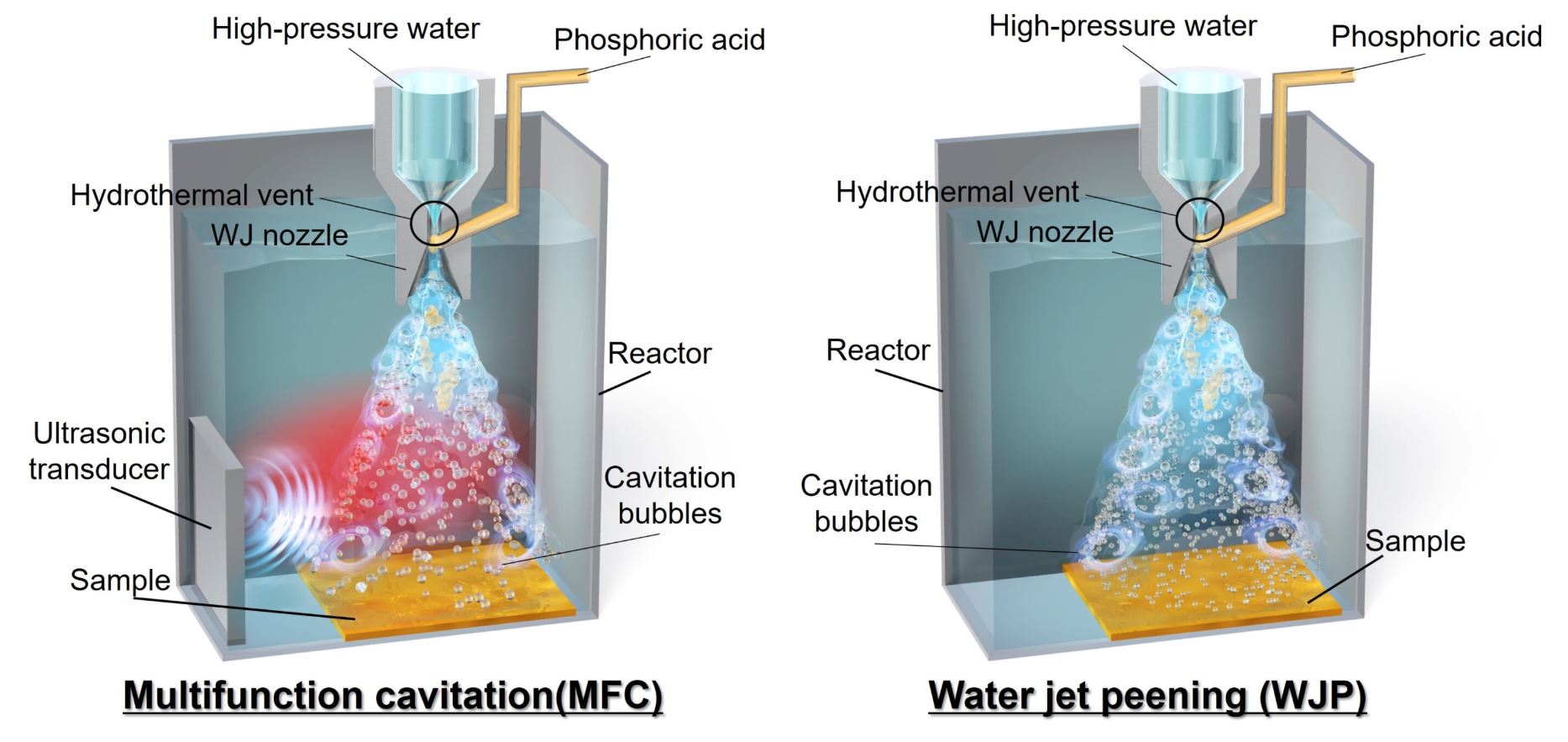

The process involves directing pressurised water and phosphoric acid onto the alloy surfaces, which triggers cavitation and forms thick magnesium phosphate films. Enhancing this effect, an ultrasonic transducer is used to energise the bubbles, resulting in a robust, corrosion‑resistant layer that outperforms traditional methods. You might appreciate knowing that, unlike many costly vacuum‑based techniques, this approach is both practical and environmentally friendly.

At a time when the automotive industry is keen to optimise efficiency and sustainability, this innovative coating could prove invaluable in extending the life and performance of lighter materials. With electrochemical tests confirming improved resistance to corrosive conditions, this development points the way to safer, more economical production techniques for electric vehicles.