Tantalum is a critical metal in many of our everyday electronic devices, yet its recovery remains challenging. Found in everything from smartphones to laptops and without any ready substitutes, tantalum is often lost in traditional recycling methods, leading to both economic and environmental setbacks.

Tantalum is a critical metal in many of our everyday electronic devices, yet its recovery remains challenging. Found in everything from smartphones to laptops and without any ready substitutes, tantalum is often lost in traditional recycling methods, leading to both economic and environmental setbacks.

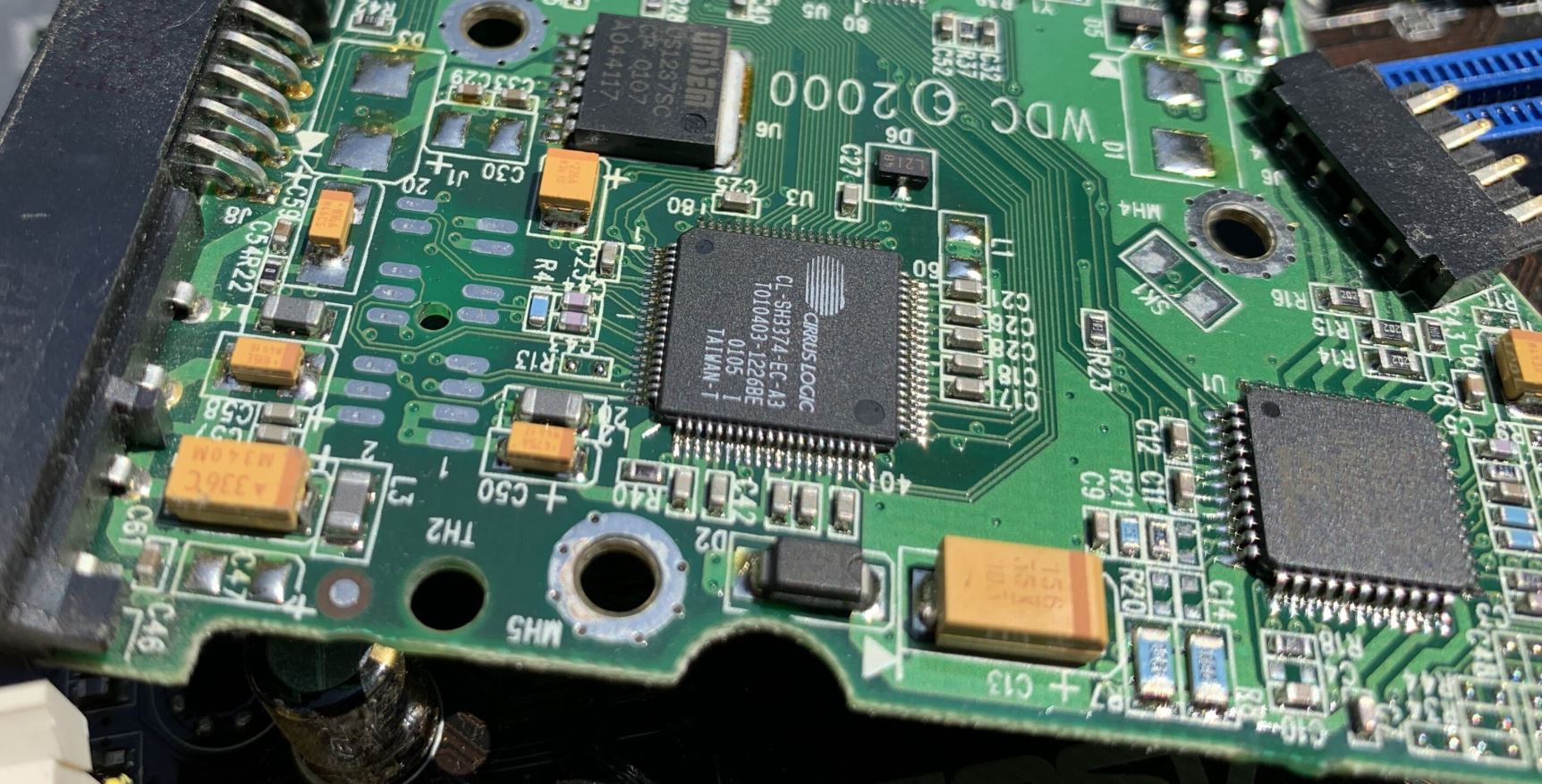

The sheer volume of electronic waste is alarming. In 2022, over 62 million metric tonnes of e-waste were generated worldwide—much of which ended up in landfills or was processed improperly overseas. This not only puts our environment at risk but also exposes communities to harmful practices, especially when dealing with scarce and geopolitically sensitive resources like tantalum.

Researchers at West Virginia University are tackling this issue in an inventive way. They shred old capacitors, mix the resulting powder with a carbon-based material, and then use microwaves to selectively heat the mixture. This method, known as carbothermal reduction, converts tantalum compounds into nearly pure tantalum carbide with over 97% purity—all achieved without harsh chemicals and with reduced energy use.

The innovation is now progressing into pilot phases, with trials on smartphone circuit boards and data centre equipment. Funded by DARPA’s Rapid Prototyping of Operational Demonstrations (RPOD) programme, this approach highlights the benefits of domestic recycling, not only from an environmental standpoint but also in terms of economic stability and national security.

If you’ve ever been frustrated by inefficient recycling methods or worried about the environmental toll of e-waste, this microwave-assisted technique offers a promising new direction. By turning what many consider trash into treasure, we can look forward to a future where recycling is both smarter and more sustainable.