MIT researchers have unveiled a fresh approach to EV battery recycling by pioneering a self‐assembling electrolyte. If you’ve ever struggled with the hassles of recycling EV batteries—often dumped into landfills because of high costs and messy chemical processes—you’ll find this development both clever and practical. Instead of focusing solely on boosting performance, the team engineered the material to break apart easily when needed, letting you recycle the battery’s components separately.

MIT researchers have unveiled a fresh approach to EV battery recycling by pioneering a self‐assembling electrolyte. If you’ve ever struggled with the hassles of recycling EV batteries—often dumped into landfills because of high costs and messy chemical processes—you’ll find this development both clever and practical. Instead of focusing solely on boosting performance, the team engineered the material to break apart easily when needed, letting you recycle the battery’s components separately.

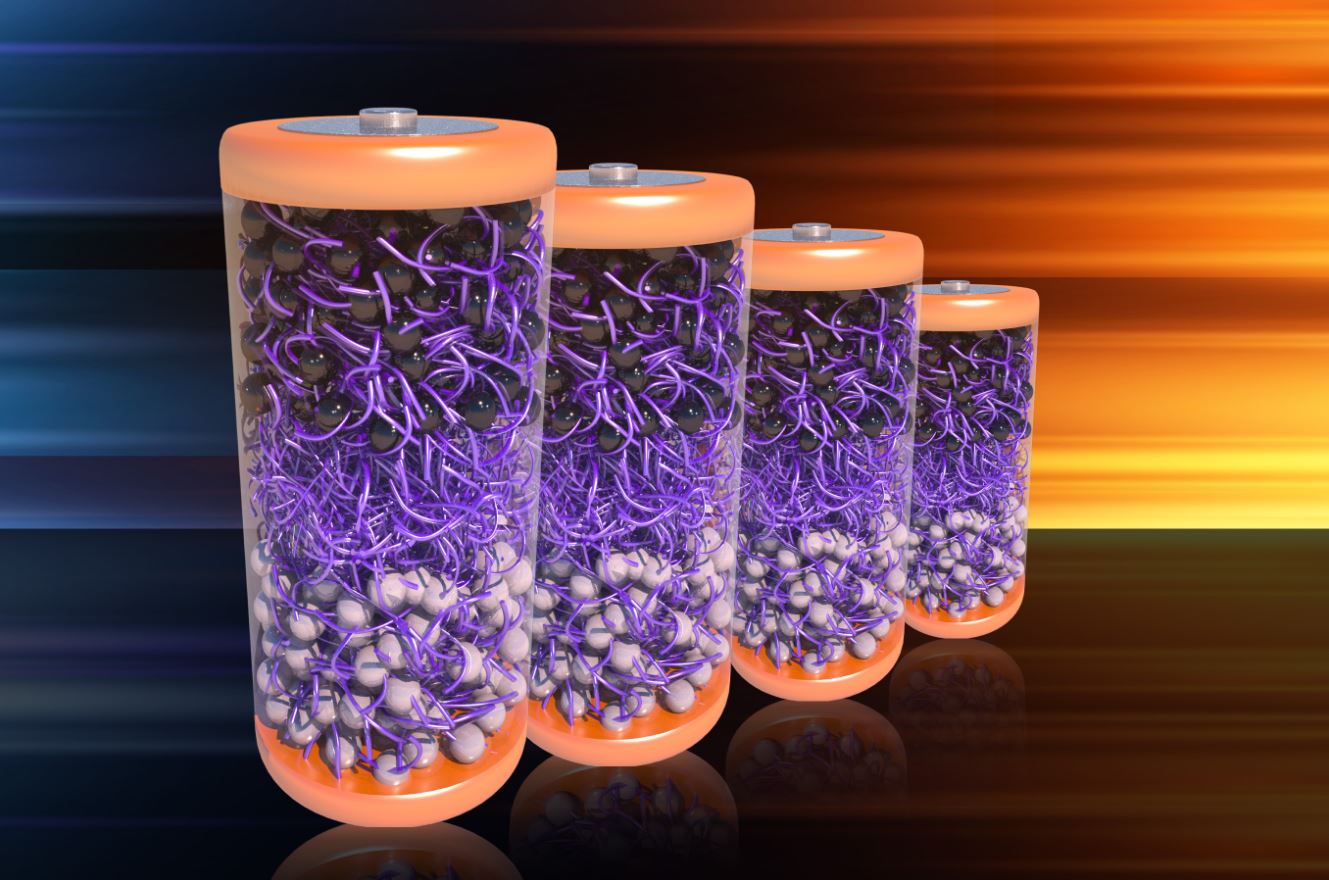

This breakthrough centres on a ‘recycle‑first’ design where the electrolyte, crucial for moving lithium ions between the battery’s cathode and anode, disintegrates quickly in a simple basic organic liquid. As lead author Yukio Cho explains, when it’s time to recycle, the whole electrolyte layer simply detaches, leaving the electrodes free for reuse.

Inspired by a touch of magic—a nod to a scene in Harry Potter—Cho and the team blended aramid amphiphiles, which self‑assemble in water much like the fibres in Kevlar, with polyethylene glycol that carries lithium ions. When these ingredients combine, they form durable nanoribbons that are hot‑pressed into a solid material. This design not only meets operational demands but also promises easier recovery of precious materials.

Of course, some challenges persist. During rapid charging and discharging, a phenomenon called polarization slows the transfer of lithium ions from the nanofibres to the metal oxide. Although ions move neatly along the fibres, that final jump remains a sticking point. Nevertheless, this proof of concept marks a significant step towards a more sustainable battery lifecycle and even hints at reclaiming lithium supplies domestically within the next five to ten years.