Imagine a world where the buildings around us not only stand tall but also help clean the air. Researchers at Northwestern University are making this vision a reality with their groundbreaking work on carbon-negative building materials. By creatively using seawater, electricity, and carbon dioxide, they’ve developed materials that capture carbon and can be used in construction. Think concrete, cement, plaster, and even paint.

Imagine a world where the buildings around us not only stand tall but also help clean the air. Researchers at Northwestern University are making this vision a reality with their groundbreaking work on carbon-negative building materials. By creatively using seawater, electricity, and carbon dioxide, they’ve developed materials that capture carbon and can be used in construction. Think concrete, cement, plaster, and even paint.

This innovation is a big step forward in tackling the challenge of storing carbon while also producing hydrogen gas, a clean fuel with many uses. Led by Alessandro Rotta Loria, the team’s study builds on past efforts to store CO2 in concrete. They’ve come up with a unique way to electrify seawater, making it possible to cement marine soils. “We’ve developed a new method that lets us use seawater to create carbon-negative building materials,” Rotta Loria explains.

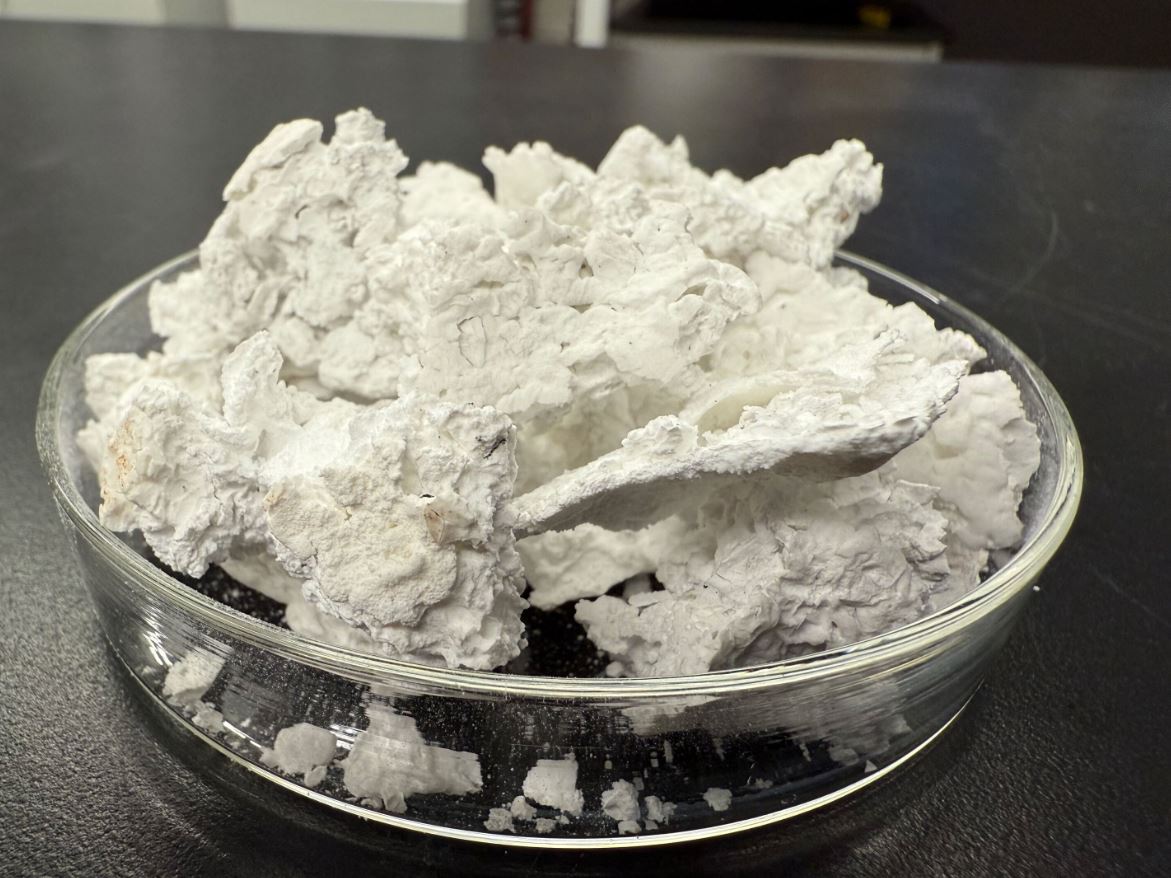

Traditionally, sand for construction is mined from natural sources. But this new process offers a fresh solution: growing sand-like materials right from seawater using electricity and CO2. It’s a fascinating approach that could change how we think about building materials.

Here’s how it works: Electrodes are placed in seawater, and an electric current is applied. This splits water molecules into hydrogen gas and hydroxide ions. When CO2 is bubbled through the seawater, the water’s chemistry changes, increasing bicarbonate ions. These ions then react with calcium and magnesium in the water to form solid minerals like calcium carbonate and magnesium hydroxide. These minerals are excellent carbon sinks, trapping CO2 effectively.

Through their experiments, researchers found they could tweak the material’s properties by adjusting factors like electrical voltage, CO2 injection timing, and seawater recirculation. The resulting materials vary in density and porosity, making them suitable alternatives to sand and gravel in concrete.

Amazingly, these materials can hold over half their weight in CO2. For example, a mix of equal parts calcium carbonate and magnesium hydroxide can store more than half a tonne of CO2 per metric tonne of material. And the best part? Using these materials doesn’t weaken the concrete or cement.

Rotta Loria points out that this method allows precise control over the chemistry of water sources and effluent, ensuring environmental safety before returning treated water to the sea. “We could create a circular system where we sequester CO2 right at the source,” he envisions. Imagine shoreline-based concrete plants using nearby ocean water in reactors to turn CO2 into useful building materials.

This exciting development not only helps address climate change but also opens up new possibilities for sustainable construction. It’s a win-win for the environment and the building industry.