Researchers at the University of Michigan have captured the first-ever 3D images of microscopic twinning in magnesium alloys, offering fresh insights into how these materials absorb stress. This isn’t just academic; it could help create lighter, stronger vehicle parts that better manage everyday pressures.

Researchers at the University of Michigan have captured the first-ever 3D images of microscopic twinning in magnesium alloys, offering fresh insights into how these materials absorb stress. This isn’t just academic; it could help create lighter, stronger vehicle parts that better manage everyday pressures.

If you’ve ever wondered why magnesium, weighing 30% less than aluminium, isn’t used more widely in cars, you’re not alone. While magnesium alloys are common in non-load-bearing components today, their unique stress response—thanks to limited slip systems and the formation of deformation twins—has held back broader adoption. These twins act like microscopic mirrors, letting the metal stretch further, though too many twins can introduce defects and cracks.

Ashley Bucsek, an assistant professor at U-M, noted, “We were surprised to find all three twins forming at triple junctions, where three crystals meet, and defects cropped up at every twin-to-crystal contact.” This consistent pattern is a promising sign that, with the right adjustments, we might be able to extend the material’s life.

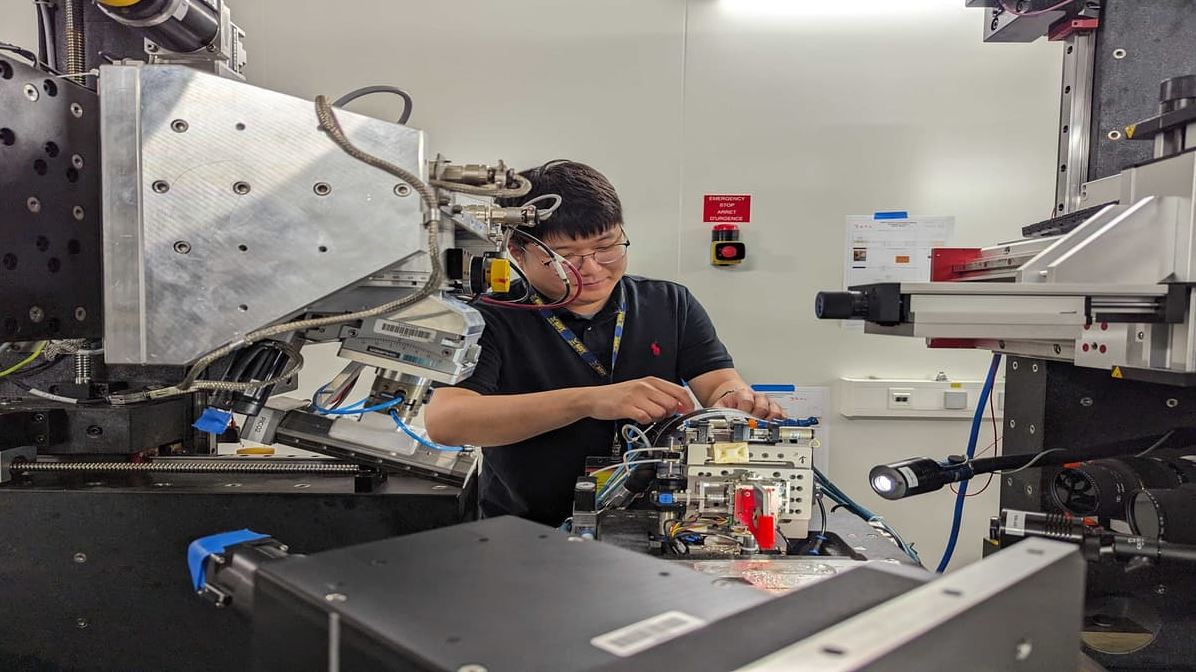

The team used dark-field X-ray microscopy—a technique where charged particles are accelerated in a synchrotron to produce high-energy X-rays—to peer into a single crystal grain as it experienced various tensile strengths (0.6, 30, and 45 MPa). By first mapping the crystal orientations with a CT scanner, they picked an optimally positioned grain to capture the twinning process as it unfolded.

You get a clear view: the transparent green polygon marks the original crystal, while red, green, and yellow planes show the freshly formed twins. Black squiggles? Those are the triple junctions where the magic—and potential problems—occur.

The research doesn’t stop here. The high-resolution 3D images not only shine a light on how magnesium alloys react under stress but also hint at how we might optimise them for safer, stronger designs. Next up, the team plans to monitor these changes in real time, an endeavour that could ultimately lead to more durable, efficient automotive parts.

This work brings together expertise from the European Synchrotron Radiation Facility, Los Alamos National Laboratory, and the National Institute of Standards and Technology, underscoring the value of collaborative research in pushing the boundaries of material science.