Imagine a world where refueling your hydrogen-powered vehicle is as quick and hassle-free as filling up with gas. Thanks to a groundbreaking innovation, we’re one step closer to that reality. Researchers have developed the first technology that prevents temperature spikes during high-pressure hydrogen charging. This could mean faster refueling times and lower costs, making hydrogen-based transportation more appealing and competitive worldwide.

Imagine a world where refueling your hydrogen-powered vehicle is as quick and hassle-free as filling up with gas. Thanks to a groundbreaking innovation, we’re one step closer to that reality. Researchers have developed the first technology that prevents temperature spikes during high-pressure hydrogen charging. This could mean faster refueling times and lower costs, making hydrogen-based transportation more appealing and competitive worldwide.

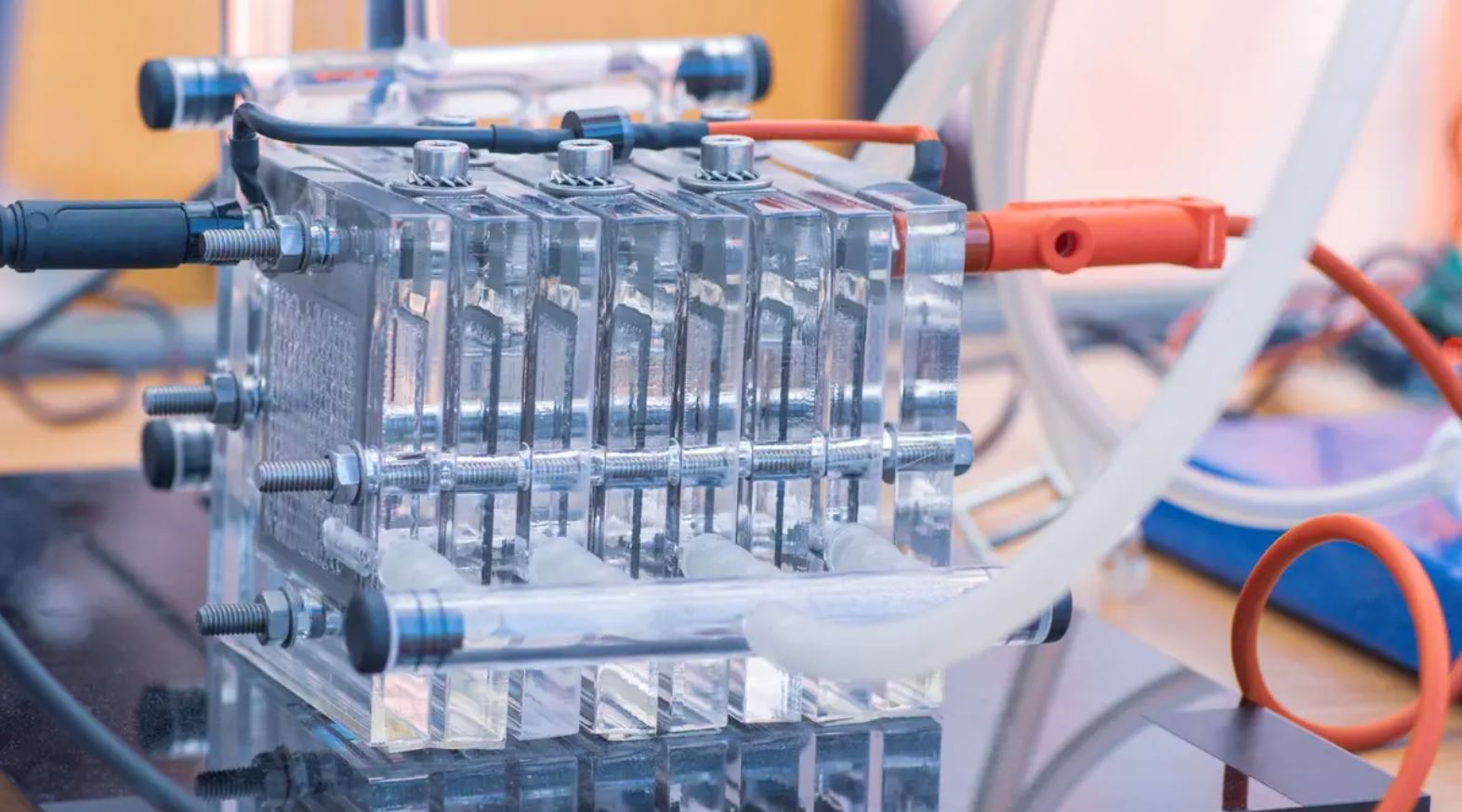

This exciting development comes from the Korea Institute of Machinery and Materials (KIMM), led by Principal Researcher Dae-Hwan Kim. The team’s approach involves using an incompressible fluid to keep temperatures in check. In tests, they managed to limit the internal temperature rise of hydrogen tanks to just 5°C, eliminating the need for pre-cooling.

Traditional methods of hydrogen refueling involve cooling the hydrogen to a chilly -40°C to avoid temperature spikes. This cooling process is not only time-consuming but also adds to the cost of hydrogen infrastructure due to the need for sophisticated cooling systems. The new method simplifies things by pre-filling the tank with an incompressible fluid like water. As hydrogen is pumped in, the fluid is removed, preventing the temperature and pressure from rising too much.

This technique speeds up the charging process and enhances safety, while also cutting down on infrastructure costs by doing away with expensive cooling systems. Plus, it helps prolong the life of tank components by reducing thermal wear and tear, which means fewer maintenance headaches down the line.

“This technology overcomes the limitations of existing hydrogen charging methods and significantly boosts infrastructure efficiency,” says Principal Researcher Dae-Hwan Kim. “We’re looking into its use not only in vehicles but also in large hydrogen containers for ships, trains, and military vehicles. It’s a game-changer for the hydrogen economy and global market competitiveness.”