Hey there! If you’ve been keeping an eye on the fight against climate change, you’ve probably noticed a lot of buzz around clean hydrogen production. It’s a hot topic because hydrogen can help us cut down on carbon emissions. One exciting method for producing hydrogen is water electrolysis. It’s promising because it doesn’t churn out carbon dioxide (CO2), but there’s a catch—it needs a lot of energy to get going, which has been a bit of a roadblock.

Hey there! If you’ve been keeping an eye on the fight against climate change, you’ve probably noticed a lot of buzz around clean hydrogen production. It’s a hot topic because hydrogen can help us cut down on carbon emissions. One exciting method for producing hydrogen is water electrolysis. It’s promising because it doesn’t churn out carbon dioxide (CO2), but there’s a catch—it needs a lot of energy to get going, which has been a bit of a roadblock.

Looking at recent numbers from the Global Carbon Project, there’s a concerning trend: global CO2 emissions from fossil fuels are expected to hit 37.4 billion tonnes in 2024. That’s a 0.8% increase from the previous year! It’s clear we need to find alternative energy solutions if we’re serious about achieving a carbon-neutral future. Despite global efforts to cut back on fossil fuels, CO2 emissions are still climbing. That’s why hydrogen, which burns cleanly without releasing CO2, is gaining traction as a viable energy alternative.

Hydrogen packs more energy than traditional solid fuels, making it a key player in balancing the ups and downs of renewable energy sources like solar and wind. Imagine converting excess electricity into hydrogen that you can store and transport. Sounds like a game-changer, right? But producing hydrogen sustainably is still tricky.

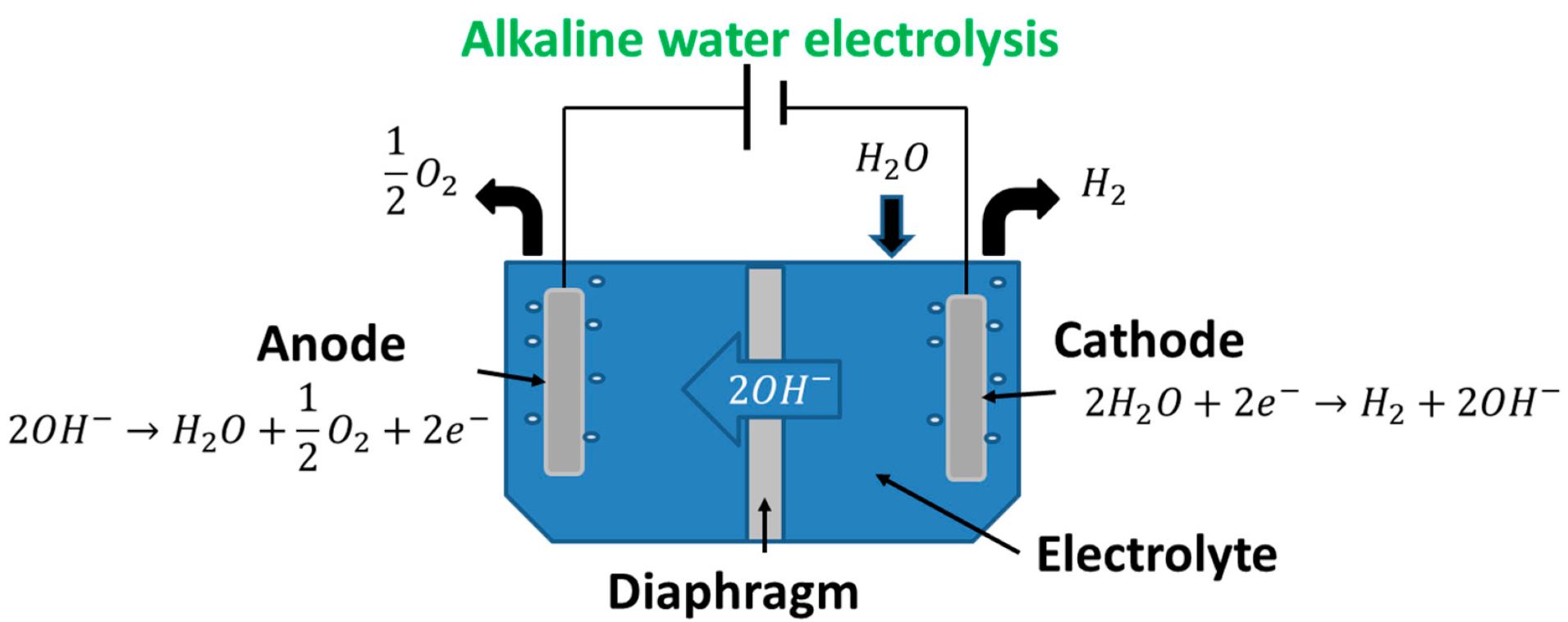

This is where chemical water electrolysis comes into play. It’s an innovative approach that could potentially solve these challenges. Instead of relying on the energy-heavy water oxidation reaction, this method uses various chemical oxidation reactions, like those involving ammonia and urea. This not only boosts energy efficiency but also creates valuable by-products or helps in getting rid of pollutants.

Professor Ho Won Jang from Seoul National University is quite optimistic about this technology. He says, ‘Chemical water-assisted electrolysis technology represents an innovative approach to overcoming the limitations of conventional water electrolysis, enabling clean hydrogen production with enhanced energy efficiency.’ But, like any promising technology, there are hurdles to jump over. Keeping catalysts durable and ensuring low-voltage operation are critical areas of focus. Researchers are diving into electrochemical reaction mechanisms and using AI to design better catalysts.

For those looking to apply this in an industrial setting, achieving high current density and ensuring long-term stability are crucial. There’s a lot of work happening around membrane electrode assemblies to cut down resistance and boost current density. Plus, high-temperature fuel cell devices and self-powered hydrogen production systems are under development.

As these innovations progress, chemical water electrolysis could become a cornerstone in our shift to sustainable energy solutions. Professor Jang sums it up nicely: ‘The main goal of this review is to quickly and accurately provide readers with the latest research trends and catalyst design strategies in this field and to outline a comprehensive blueprint for industrial applications.’