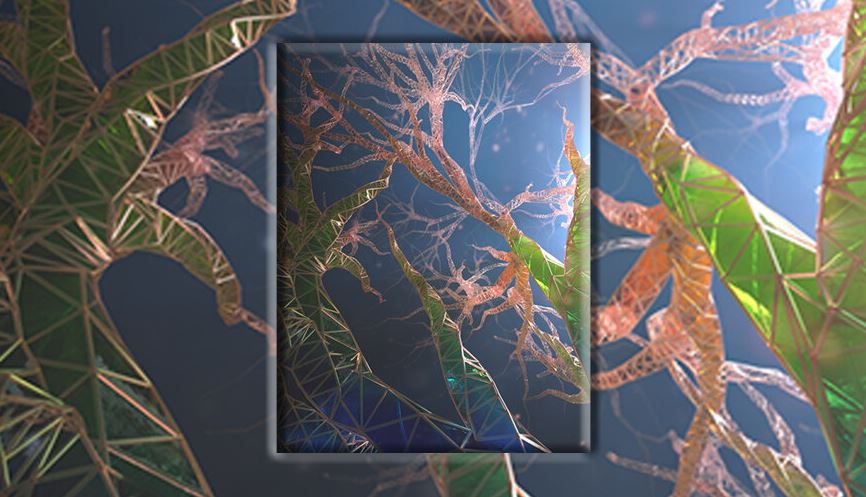

Scientists have developed an exciting new method for creating multi-material structures, introducing a technique called cellular fluidics.

This approach makes it possible to combine materials with completely different properties in ways that were once impossible, opening new doors in soft robotics, biomedical engineering, and advanced manufacturing.

At its core, cellular fluidics uses tiny, liquid-filled compartments—similar to biological cells—that can be programmed to assemble materials in precise arrangements.

This is a big shift from traditional manufacturing methods, which rely on rigid structures and are often limited in the types of materials they can fuse together.

A Major Breakthrough in Material Integration

By allowing engineers to seamlessly integrate flexible, rigid, and dynamic components into a single design, this technique opens the door to materials that are not only more adaptable but also more efficient in their performance.

Potential Applications

The potential applications of cellular fluidics are impressive, with promising possibilities in several fields:

- Soft Robotics: Engineers could design robots with multi-material structures that better mimic biological movement.

- Biomedical Engineering: This technology could help create more precise, patient-specific implants or advanced drug delivery systems tailored to individual needs.

Cellular Fluidics Application in Fusing Materials for Soft Robots

Cellular fluidics hold significant potential for integrating and fusing diverse materials in soft robots, addressing challenges like multifunctionality, adaptability, and self-healing. Here’s how:

- Multi-Material 3D Printing Integration

Cellular fluidics leverage emerging 3D printing methods to create hierarchical, porous architectures. This allows the simultaneous incorporation of conductive, flexible, and responsive materials into a single structure. For example, soft robots with embedded electrohydrodynamic (EHD) pumps—critical for untethered actuation—have been fabricated using multi-material 3D printing, combining conductive thermoplastic polyurethane (TPU) electrodes and non-conductive TPU supports. Such integration is vital for merging rigid actuators with soft, deformable components. - Programmable Fluid Pathways for Material Deposition

The deterministic control of fluid flow in cellular fluidics enables selective material deposition. For instance, capillary-driven or actively pumped liquid flow can direct functional materials (e.g., self-healing polymers, conductive inks) to specific regions within a robot’s structure. This has been demonstrated in cellular fluidic devices that metallize pre-programmed patterns, showcasing their ability to fuse metallic and polymeric materials. - Self-Healing Material Systems

Soft robots often suffer damage, but cellular fluidics can facilitate the fusion of self-healing materials. Researchers have developed “healing electrofluids” that solidify upon exposure to air to repair large-area damage. These fluids are pumped through cellular fluidic pathways, enabling rapid (<6 hours) self-repair of silicone-based robots. The 3D-printed porous structures ensure uniform fluid distribution, critical for consistent material fusion. - Enhanced Actuation and Sensing

By embedding functional fluids (e.g., dielectric liquids for EHD pumps) within cellular architectures, soft robots achieve high-speed actuation and intelligence. For example, liquid-metal-based E-skins integrated into cellular fluidic systems enable real-time damage detection and adaptive responses, merging sensing and actuation materials seamlessly. - Biomimetic Design for Adaptive Material Interfaces

Cellular fluidics mimic natural systems like plant vasculature, enabling dynamic material interactions. For instance, bioinspired microchannel designs allow for anti-gravity fluid transport, which could be adapted to fuse phase-changing materials or stimuli-responsive polymers in soft robots

Early Experiments Show Exciting Results

Early experiments have already shown that cellular fluidics can produce intricate structures that conventional methods struggle to achieve.

Unlike standard layering or additive manufacturing, this technique offers a fine-tuned, highly adaptable process, making it easier to develop complex materials quickly and efficiently.

The Future of Cellular Fluidics

Looking ahead, researchers believe cellular fluidics could completely change how we think about material design and manufacturing.

With further development, it has the potential to become a key technology in everything from futuristic medical devices to next-generation consumer products.