Electric vehicles (EVs) are becoming more popular worldwide, but their lithium-ion batteries still come with safety concerns—especially when it comes to lithium plating. This occurs when lithium metal builds up on the battery’s anode surface during charging, which can shorten battery life and even create serious safety risks. To tackle this, a team from the University of Shanghai for Science and Technology has developed an AI-driven detection system that could make a real difference.

Electric vehicles (EVs) are becoming more popular worldwide, but their lithium-ion batteries still come with safety concerns—especially when it comes to lithium plating. This occurs when lithium metal builds up on the battery’s anode surface during charging, which can shorten battery life and even create serious safety risks. To tackle this, a team from the University of Shanghai for Science and Technology has developed an AI-driven detection system that could make a real difference.

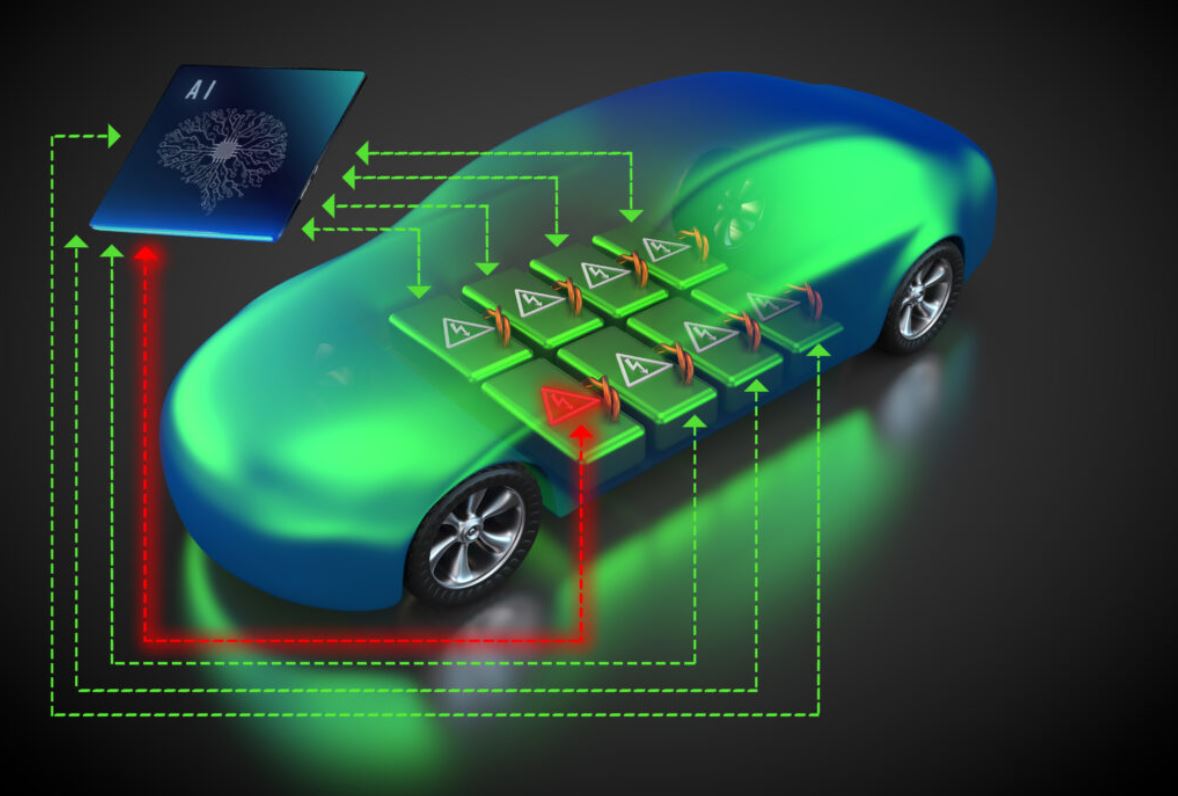

The system uses artificial intelligence to analyse standard electrical signals from the battery, reaching a detection accuracy above 97%. What’s impressive is that it achieves this without needing costly hardware changes, making it easier for manufacturers to adopt and improve battery safety and durability.

Here’s why lithium plating matters: instead of lithium ions slipping neatly between graphite layers in the anode, they sometimes deposit as metallic lithium on the surface—often during fast charging or in cold conditions. This can lead to dendrites, tiny needle-like structures that risk causing short circuits and fires. Detecting these problems early has been tricky, but this AI approach offers a practical solution.

The Shanghai researchers built their detection tool around the Random Forest machine learning algorithm. By examining data collected during pulse charging, the system picks up patterns that signal lithium plating. It’s been tested using signals from existing battery management systems (BMS), achieving over 97.2% accuracy without any physical battery modifications. This means it can slot into current EV platforms with minimal hassle.

A key to the system’s success is its multi-dimensional feature extraction. While looking at just one variable gave around 68.5% accuracy, combining features like internal resistance and voltage relaxation boosted detection significantly. This lets the system predict faults early and deliver real-time insights into battery health and safety.

Because it works as a software upgrade for current BMS units or can be integrated into cloud-based management tools, EV makers and energy storage companies can adopt it quickly—no redesign needed. The team also plans to extend this approach to other lithium-ion uses, such as smartphones and grid storage, with future versions adapting to fast-charging conditions.

As EVs continue to replace traditional vehicles, making sure their batteries are reliable and safe is crucial. This AI-powered lithium plating detection system gives manufacturers a valuable tool to extend battery life and build user confidence in electric transport. It’s a great example of how smart data analysis can help solve tough engineering problems and move us toward cleaner, safer energy.